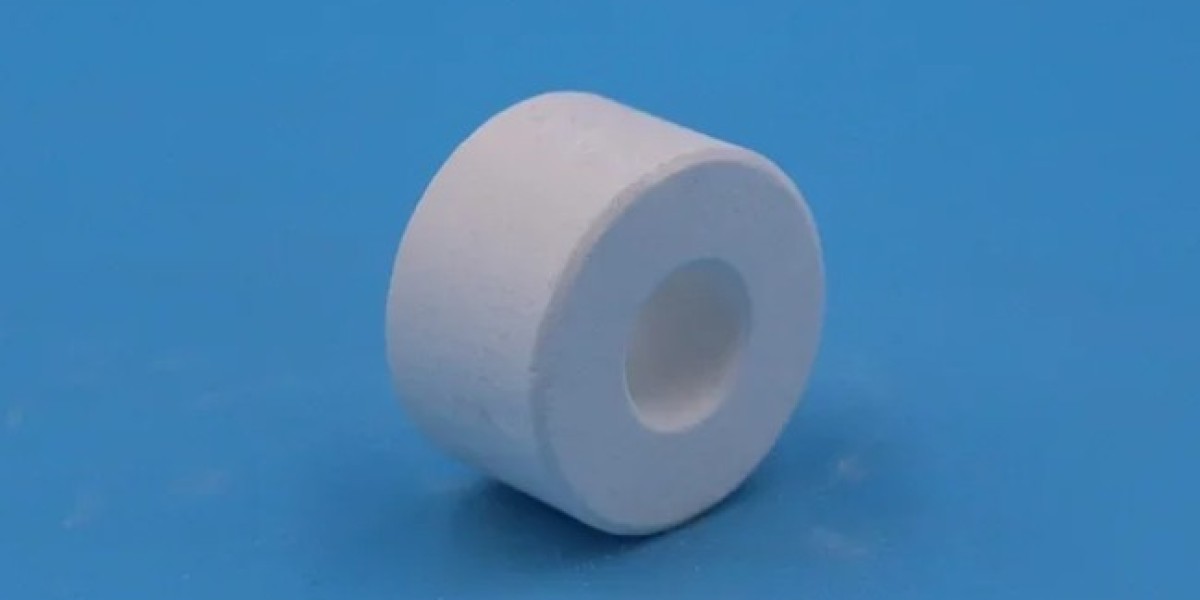

Steam reforming is a widely used process in the production of hydrogen, ammonia, and other valuable chemicals. It involves the conversion of hydrocarbons, such as natural gas or methane, into hydrogen and carbon monoxide through a catalytic reaction. The catalyst carrier plays a crucial role in this process, providing a high surface area for the catalyst and facilitating the desired chemical reactions. In this article, we will delve into the properties of alumina-based catalyst carriers and their significance in steam reforming applications.

1. Alumina as a Catalyst Carrier

Alumina, also known as aluminum oxide (Al2O3), is a popular choice for catalyst carriers due to its unique properties. It possesses high thermal stability, excellent mechanical strength, and a large surface area, making it suitable for various catalytic reactions. In steam reforming, alumina-based catalyst carriers offer several advantages.

2. High Surface Area

One of the key requirements for an effective catalyst carrier is a high surface area. Alumina-based carriers typically have a large number of pores and a high specific surface area, providing ample space for the catalyst to interact with the reactants. This increased surface area enhances the catalytic activity and promotes better conversion rates in steam reforming.

3. Pore Structure

The pore structure of a catalyst carrier significantly influences its performance in steam reforming. Alumina-based carriers can be tailored to have different pore sizes and distributions, allowing for control over reactant diffusion and catalyst accessibility. The presence of both macropores and mesopores in alumina carriers facilitates the transport of reactants and products, ensuring efficient mass transfer during the reaction.

4. Thermal Stability

Steam reforming operates at high temperatures, typically above 700°C. Alumina-based catalyst carriers exhibit excellent thermal stability, maintaining their structural integrity even under extreme conditions. This stability prevents catalyst deactivation and ensures the longevity of the catalyst system, making alumina carriers a reliable choice for steam reforming applications.

5. Resistance to Sintering

Sintering refers to the undesirable process of catalyst particles agglomerating and losing their active surface area. Alumina-based carriers have a high resistance to sintering, thanks to their strong chemical bonds and thermal stability. This property helps to maintain the catalyst's active sites and prolong the catalyst's lifespan, resulting in improved steam reforming efficiency.

6. Promoting Catalyst Dispersion

The dispersion of the catalyst on the carrier surface is crucial for achieving high catalytic activity. Alumina carriers possess a high affinity for catalyst materials, promoting better catalyst dispersion and preventing catalyst aggregation. This uniform distribution of catalyst particles enhances the catalytic performance and ensures efficient utilization of the active sites.

7. Catalyst Support Interaction

The interaction between the catalyst and the carrier material is another important aspect to consider. Alumina-based carriers offer a strong support-catalyst interaction, which can enhance the catalyst's stability and activity. This interaction can be further optimized by modifying the surface chemistry of the alumina carrier, tailoring it to specific catalyst requirements.

Conclusion

Alumina-based catalyst carriers exhibit several desirable properties for steam reforming applications. Their high surface area, tailored pore structure, thermal stability, resistance to sintering, and ability to promote catalyst dispersion make them an excellent choice for supporting catalysts in steam reforming reactions.

Yixing Winner Technology Co., Ltd. is a professional manufacturer in producing catalysts and their ceramic carriers, ceramic glove formers, and other industrial ceramics.

Welcome to inquiry if you need to know more about Alumina-based Catalyst Carriers details or order wholesale.